Vacuum dry cleaning in the cleanroom with RGA

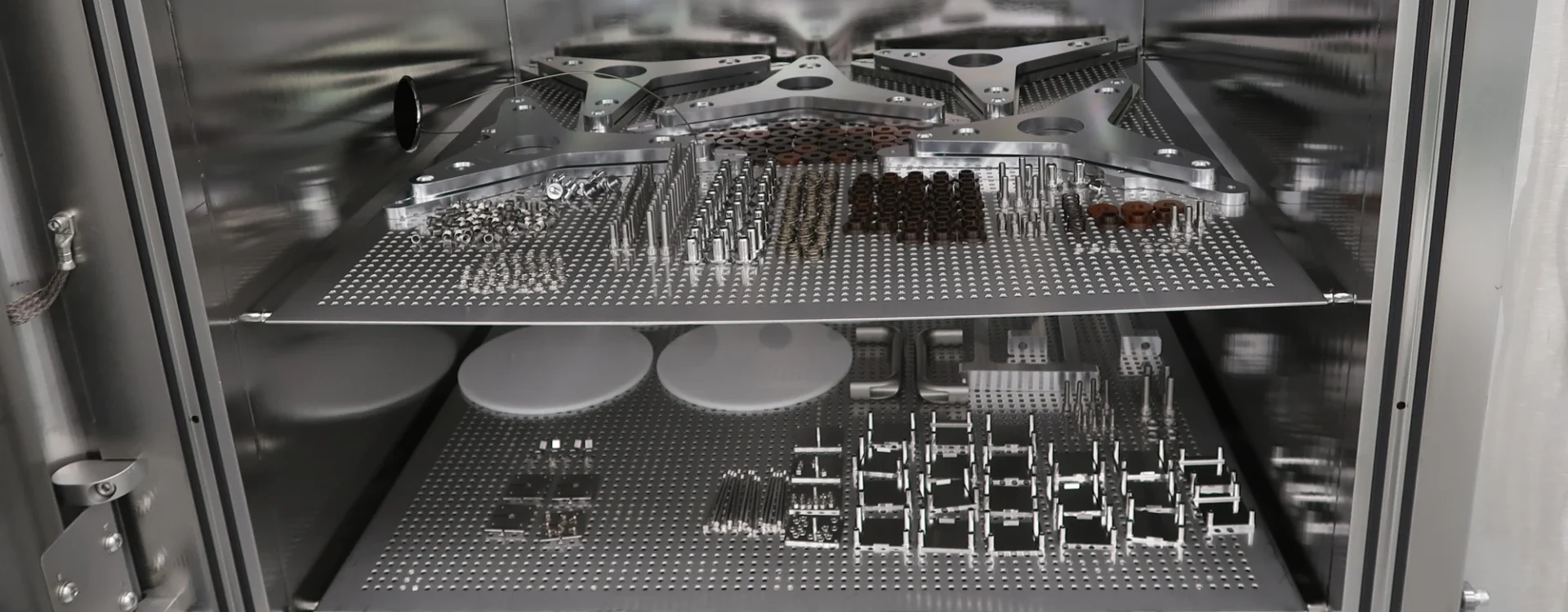

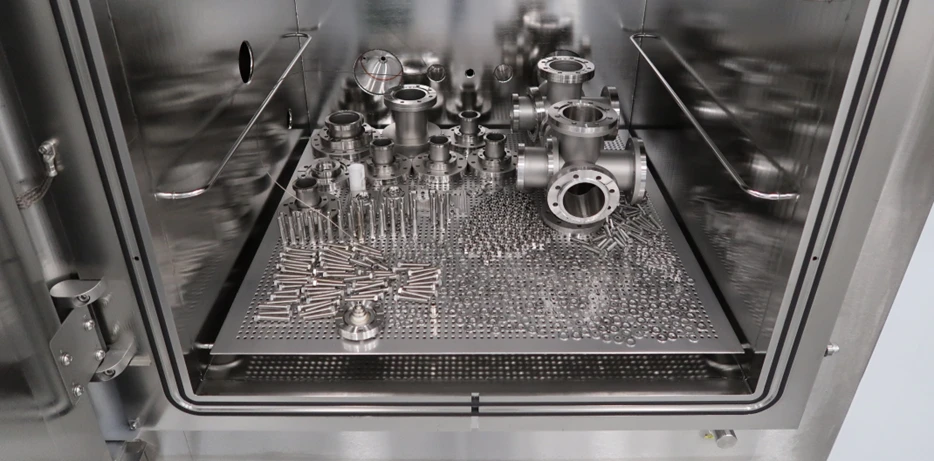

Vacuum dry cleaning in the cleanroom? Parts, assemblies and devices for cleaning water, volatile and non-volatile hydrocarbons in our ultra-high vacuum dry cleaning system. Rely on our extensive know-how and expertise in the cleanroom environment!

ADVANTAGES OF OUR VACUUM DRY CLEANING

- One highlight is our vacuum dry cleaning with RGA (residual gas analysis)

- Cleaning components from water, volatile and non-volatile hydrocarbons

- Optional heating of components up to 150 °C

- Logging and analysis of desorption rates

- Cleanroom-compatible packaging

- Your parts are delivered punctually, on time and just in time

- CNC production, assembly or fixture construction AND cleaning under one roof

Cleaned, checked with RGA, ready for dispatch

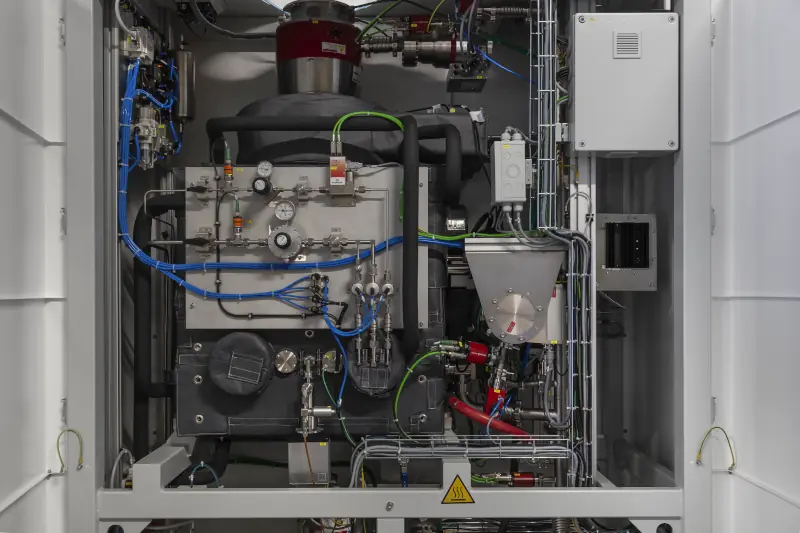

The system is operated and loaded in an ISO 5 clean room. No prohibited materials may be used inside the chamber or on any components in contact with the vacuum.

Features

- Chamber size inside: 750x750x750 mm, larger components possible

- Optional component bake-out process can be parameterized (time / temperature up to 150 °C)

- Detection limits:

○Q(H2O): < 1E-10 mbar*l/s/cm2

○ Q(CxHy v): < 1E-12 mbar*l/s/cm2

○ Q(CxHy nv): < 1E-13 mbar*l/s/cm2

- Evaluation of outgassing rates for specific substances (e.g. acetone/limonene) possible

- Customized limit values and detailed logging with individual design

- Database-based storage of results for component comparison

By the way: We also offer our cleanroom product cleaning as a contract service. Manufacturers of individual parts and/or assemblies can use our parts cleaning service without having to keep the complex systems ready themselves and acquire the expertise we have.